Product Detail

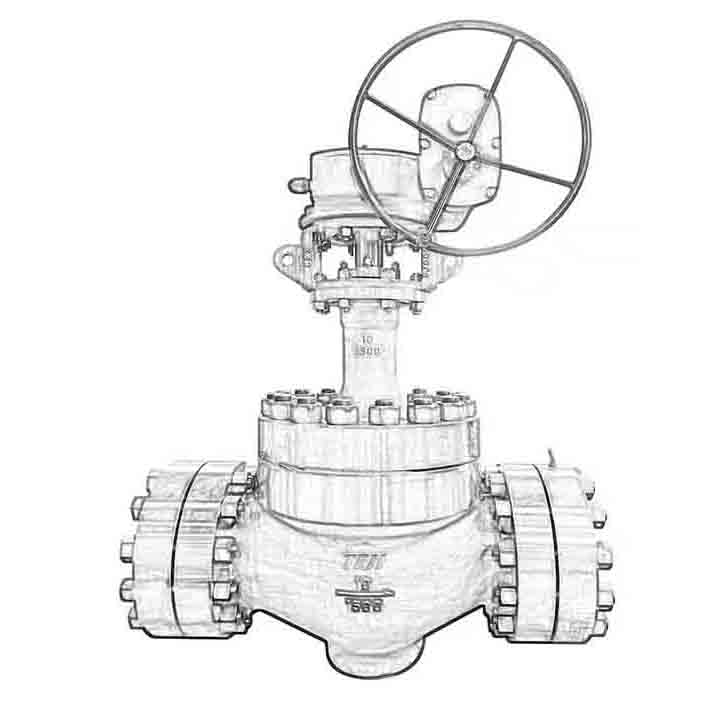

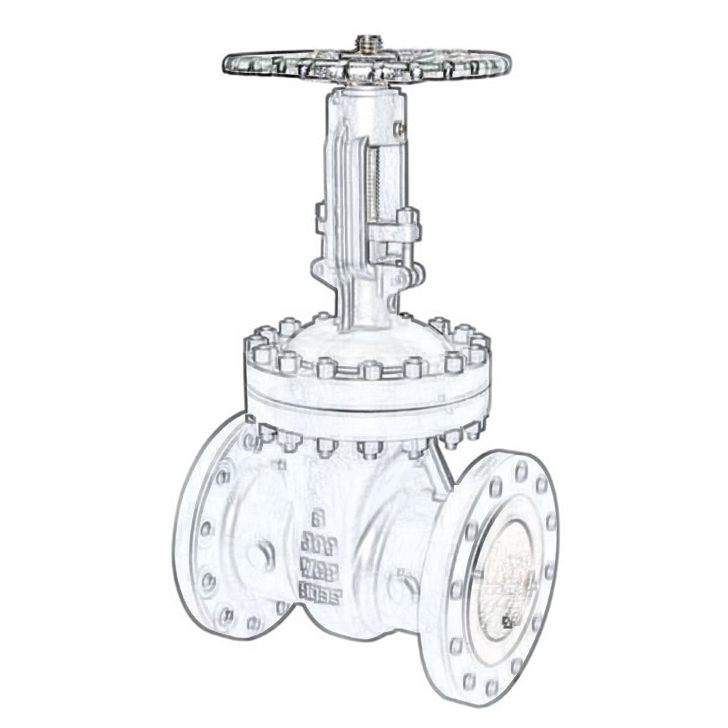

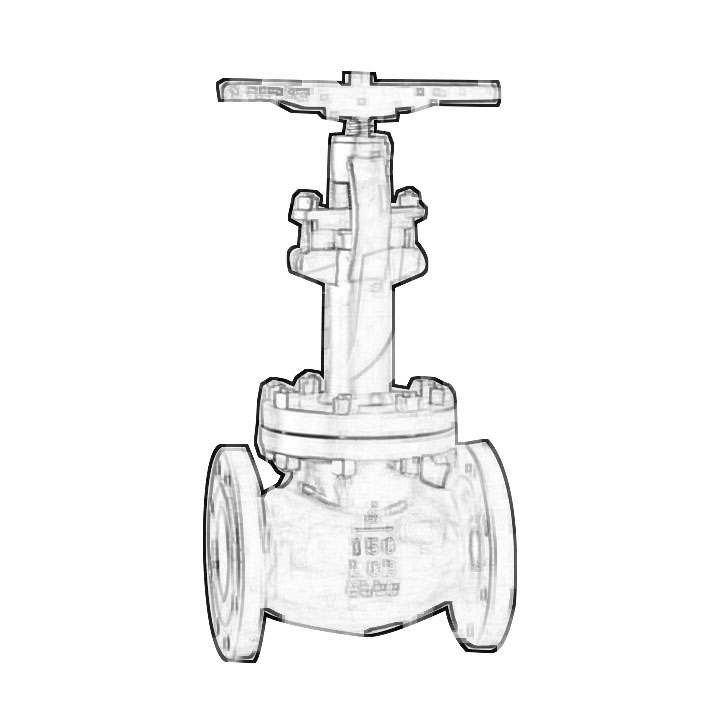

Cast Steel Cryogenic Globe Valve

Cryogenic Globe Valve refers to a valve whose disk moves along the center line of the valve seat.

- category :Cast Steel Cryogenic Valves

- Email :teji@teji-valve.com

- Phone :+86-577-67354000

- fax :+86-577-67354001

Cryogenic Globe Valve refers to a valve whose disk moves along the center line of the valve seat. According to this movement form of the valve disc, the change of the valve seat port is proportional to the valve disc stroke. This valve’s opening or closing stroke of the valve stem is relatively short, and it has a very reliable shut-off function, and due to the change of the valve seat port is in direct proportion to the stroke of the valve disc, so it is very suitable for use as a shut-off or adjustment and throttling.

Applicable Medium: Cryogenic temperature medium like Methane/Liquid natural gas/Hexene/Carbon dioxide/Liquid ammonia/Liquid oxygen/Liquid nitrogen/Liquid hydrogen and so on.

SPECIFICATIONS:

1.Valve Size : 2 ~ 24”

2.Applicable Rating : ASME 150# ~ 1500#

3.Temperature : Down to -196 ℃

4.Code & Standard : BS, ASME, ASTM

Designed by BS6364, ASME B16.34, and ASME B16.25/16.5

5.Shell & Seat Leak Test : ASME B16.34.

6.Constructions:

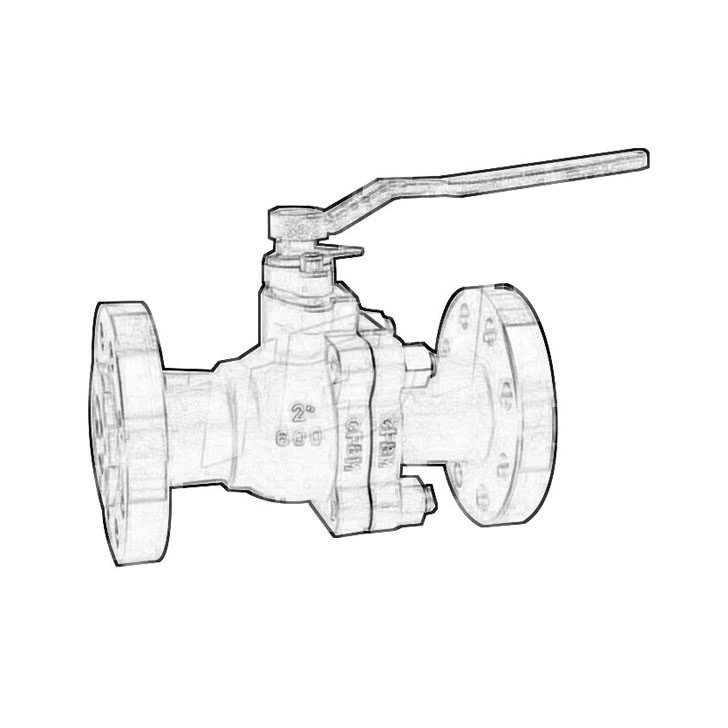

End Connection : Flanged, Butt-Welded or RTJ Type

Long Extended Bonnet

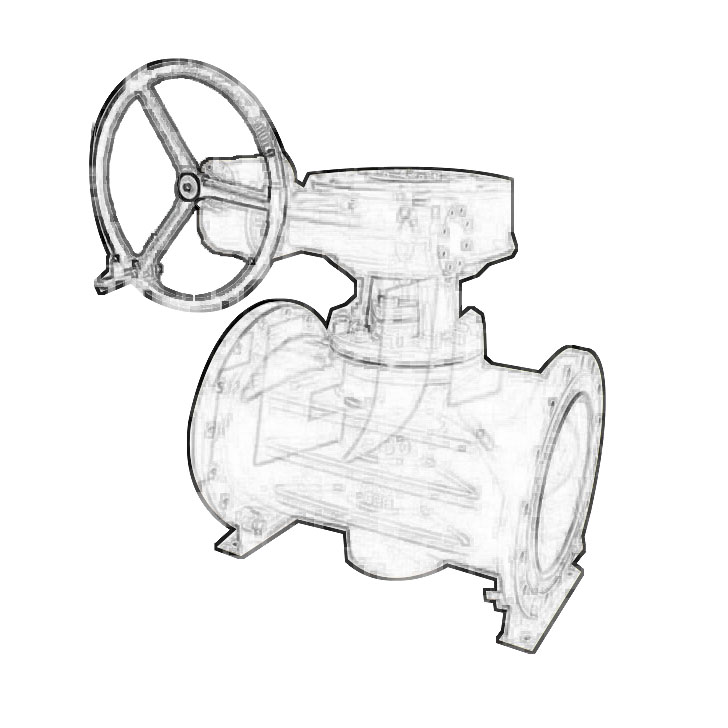

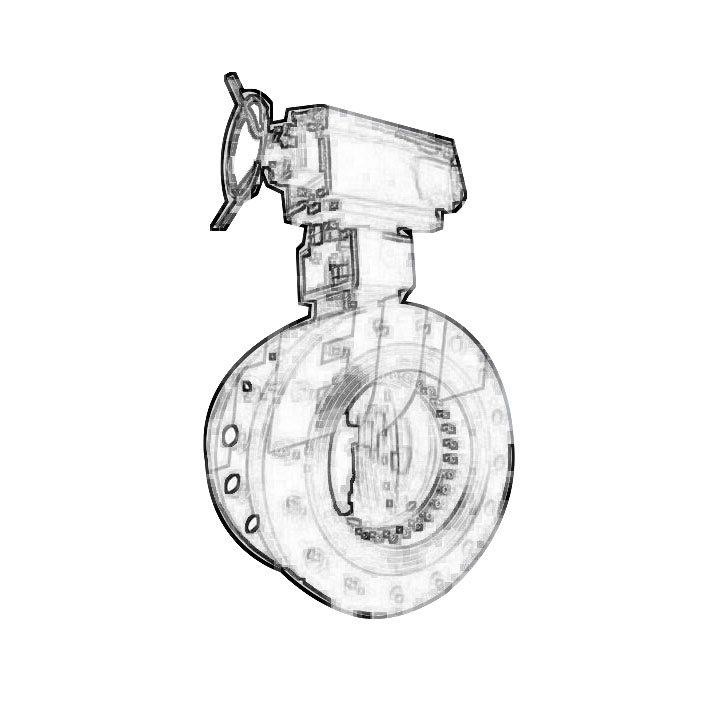

Operator : Gear-operated Type

Pressure Relief Design(Pressure Balance Design)

Fire Safety / Anti-static Design

FEATURE:

1.The structure is simpler than the gate valve, and it is more convenient to manufacture and maintain.

2.The sealing surface is not easy to wear and scratch, and the sealing performance is good. There is no relative sliding between the valve disc and the sealing surface of the valve body when opening and closing, so the wear and scratches are not serious, the sealing performance is good, and the service life is long.

3.When opening and closing, the disc stroke is small, so the height of the stop valve is smaller than the gate valve, but the structure length is longer than the gate valve.

4.The opening and closing moment is large, the opening and closing is more laborious, and the opening and closing time is longer.

5. The fluid resistance is large, because the medium passage in the valve body is tortuous, the fluid resistance is large, and the power consumption is large.

6. The disc is often eroded when fully opened.

MATERIALS FOR MAIN PARTS:

|

PARTS NAME |

MATERIAL |

|

BODY |

Cast Steel - ASTM A351-CF8(M)/CF3(M) |

|

BONNET |

Cast Steel - ASTM A351-CF8(M)/CF3(M) |

|

SEAT |

ASTM A276-304L(H.F) |

|

DISK |

ASTM A276-304(L)(H.F) / 316(L)(H.F) or Equivalent |

|

STEM |

ASTM A276-316(L) |

|

GASKET |

SPIRAL WOUND GRAPHITE |

|

GLAND PACKING |

GRAPHITE |

|

Welcome to our website. If you have any requests or suggestions,please feel free to email us at teji@teji-valve.com or use the following enquiry form. Please allow us to provide you with the best service.