Product Detail

Cryogenic Ball Valve

- category :Cryogenic Ball Valves

- Email :teji@teji-valve.com

- Phone :+86-577-67354000

- fax :+86-577-67354001

Product Introduction

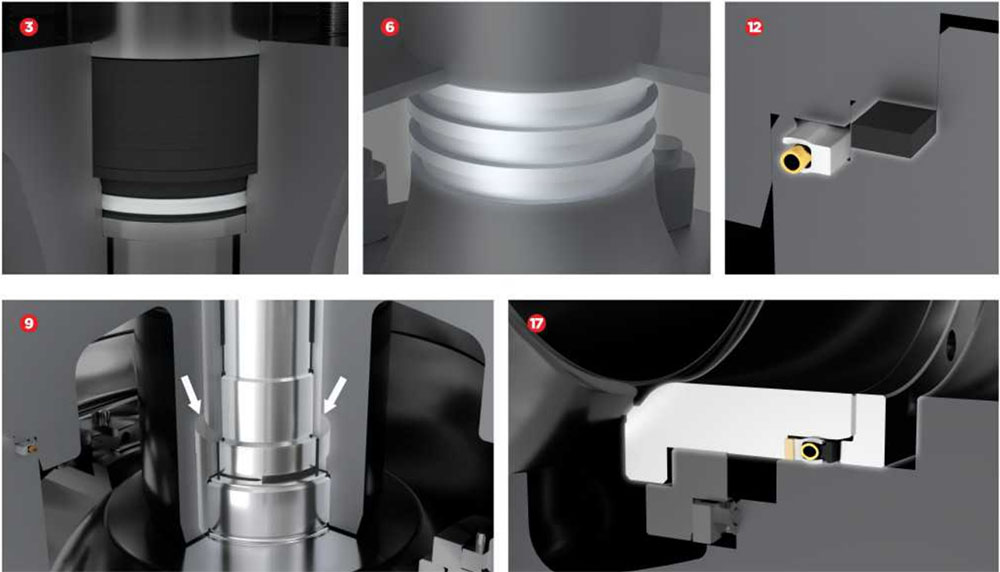

1.Precision machining procedure, controling the gap of stem and extend bonnet below 1mm, guarantee the smooth turning of stem, and also reduced the possibility of freezing and losing caused by cryogenic service.

2.The lip-seal is not only have the flexible compensation function as Spring, but also excellent sealing as PTFE. Excellent sealing under cryogenic temperature, fire safe design as the secondary sealing of graphite.

3.All the faster is full threaded construction for cryogenic temperature, it is effectively avoid faster long deformation and sealing failed.

Design Feature

Technical Property

1.Stem: double sealing design, the primary sealing is lip seal, secondary sealing is packing, which can reduce the amount of packing usage.

2.Extended bonnet design: the gap between and extention parts is strictly controlled, which reduce the cryogenic service crossing up, avoiding the packing freezing and torque larger to make stem scratched.

3.Self centering design on gland flange and packing to avoid stress imbalance.

4.By FEA design, best thickness of extended bonnet is calculated, it would guarantee the best cooling effect.

5.Extended bonnet with ARC design, enlarged the cooling area, strengthen the cooling results.

6.The design of drip plate, it firstly enlarged the effective cooling area, avoid the freezing problem of stem and packing dynamic sealing area resulted larger torque; secondly, it effectively stop the condensate water drop into body resulted in body double sealing on connection of body bonnet.

7.It’s primary sealing is lip-seal, it’s secondary sealing is gasket.

8.DIB-2 seat construction, which can guarantee the body pressure would be released to another without any danger.

9.Lip-seal sealing construction, the lip-seal is not only have the flex, compensation as spring, but also have excellent flexible, sealing property as PTFE, this combined using can promise the effective sealing under cryogenic condition.

10.Imported PCTFE used as seat sealing, it has good flexible function under cryogenic condition, promising it’s sealing.

11.Extended stem design, make sure the better self-centering of bushing. Stem and bonnet, opening smoothly.

12.The ball hardened to make sure no scratching under cryogenic temperature.

13.Trim top entry construction for online maintain.

Welcome to our website. If you have any requests or suggestions,please feel free to email us at teji@teji-valve.com or use the following enquiry form. Please allow us to provide you with the best service.