Product Detail

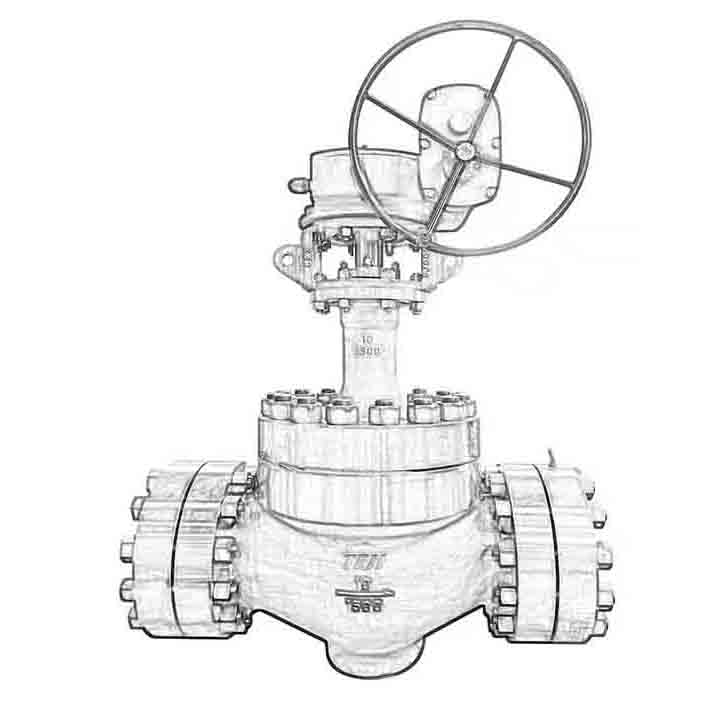

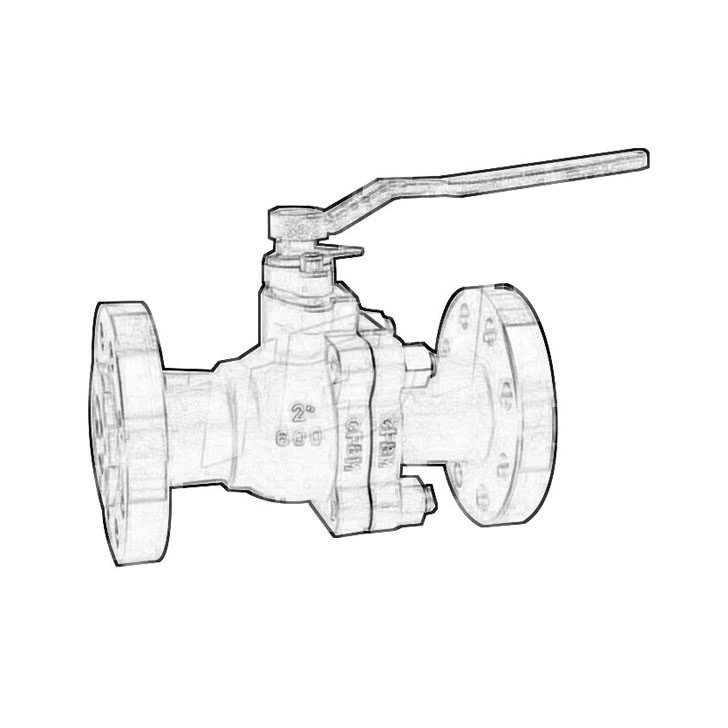

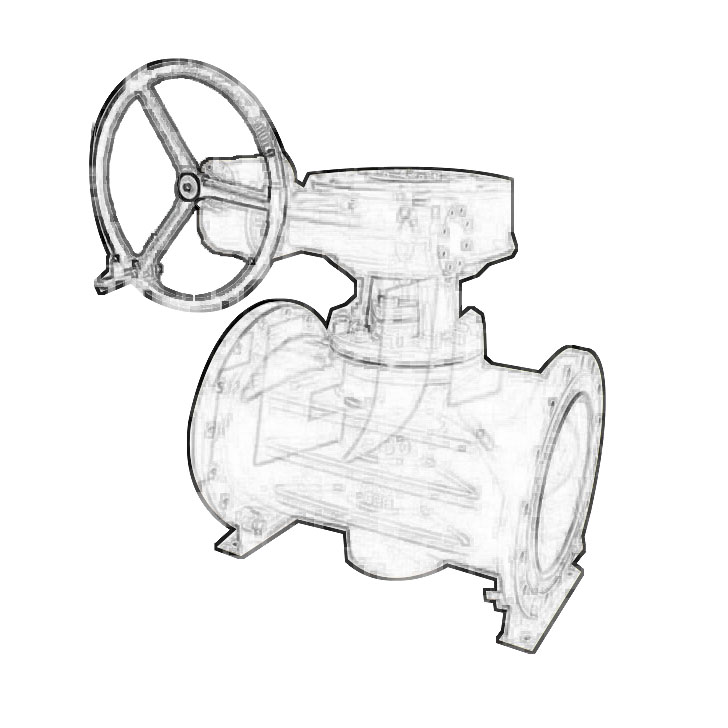

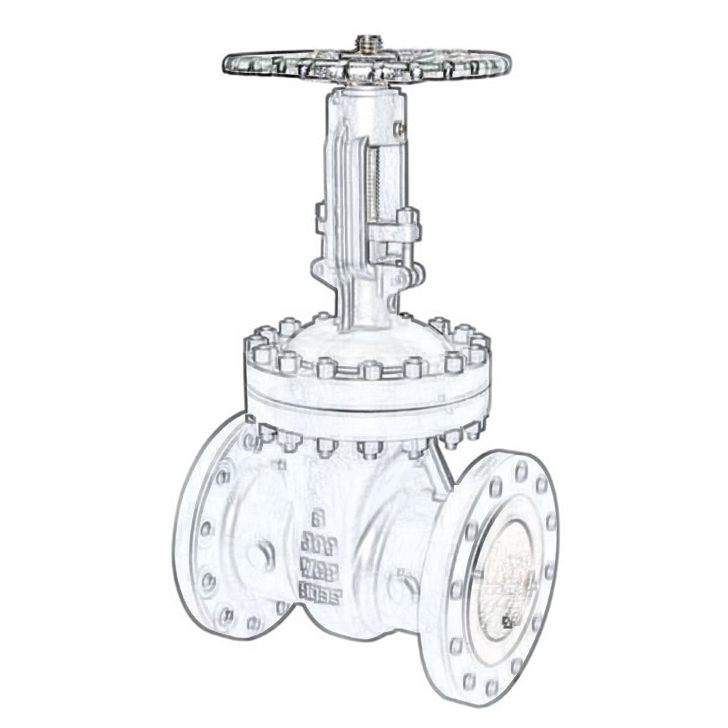

Cryogenic Top-Entry Ball Valve

The Cryogenic Top-Entry Ball Valve, as an important on/off component in the cryogenic pipeline system, is an important part of the petrochemical industry, air separation, and natural gas industry.

- category :Cryogenic Ball Valves

- Email :teji@teji-valve.com

- Phone :+86-577-67354000

- fax :+86-577-67354001

The Cryogenic Top-Entry Ball Valve, as an important on/off component in the cryogenic pipeline system, is an important part of the petrochemical industry, air separation, and natural gas industry. The structure of Top-Entry Ball Valve can realize online maintenance, and is suitable for low-temperature liquid or gas media, such as liquefied natural gas (LNG), liquefied petroleum gas (LPG), liquid hydrogen, liquid oxygen, ethylene and other conditions. Compared with the Side-Entry ball valve under the same conditions, Top-Entry Ball Valve is more convenient to maintain with a wider scope of application, and is more common.

SPECIFICATIONS:

1. Valve Size : 1/2” ~ 20” (Cast Steel) / 1/2” ~ 36” (Forged)

2. Applicable Rating : ASME 150# ~ 1500#

3. Temperature : Down to -196 ℃

4. Code & Standard : API, BS, ASME, ASTM

Designed by BS5351, ASME B16.34, and ASME B16.25/16.5

5. Shell & Seat Leak Test : API 598 & BS6364

6. Constructions:

End Connection : Socket-Welded, Butt-Welded or Flanged Type

Long Extended Bonnet

Trunnion Ball,Floating Ball, Full Bore / Reduce Bore

Fire Safety Construction(Certified by TÜV)

Manual or Motor Operated (Pneumatic, Electric, or Hydraulic)

Uni- / Bi-Direction, Double Block & Bleed Design

FEATURE:

1. The structure of Top-Entry Ball Valve enables online valve maintenance.

2. Extended bonnet design.

3.Design of live-loaded seal structure of valve stem.

4.Special design of valve seat assembly, reliable sealing, detachable valve seat structure.

5.Valve cavity overpressure relief design.

6.Stem anti-settling design.

7.The extended bonnet has a drip tray design, which can effectively prevent condensate from flowing into the insulation layer.

8.Fire-resistant, anti-static, anti-stem ejection function.

MATERIALS FOR MAIN PARTS:

|

PARTS NAME |

MATERIAL |

|

BODY |

Forged Steel - ASTM A182-F304(L)/F316(L) / Cast Steel - ASTM A351-CF8(M)/CF3(M) |

|

BONNET |

Forged Steel - ASTM A182-F304(L)/F316(L) / Cast Steel - ASTM A351-CF8(M)/CF3(M) |

|

SEAT |

PCTFE / GRAPHITE |

|

BALL |

ASTM A276-304(L) / 316(L)-(H.F) |

|

STEM |

ASTM A276-304(L) / 316(L) |

|

GASKET |

SPIRAL WOUND GRAPHITE |

|

GLAND PACKING |

GRAPHITE |

Welcome to our website. If you have any requests or suggestions,please feel free to email us at teji@teji-valve.com or use the following enquiry form. Please allow us to provide you with the best service.