Product Detail

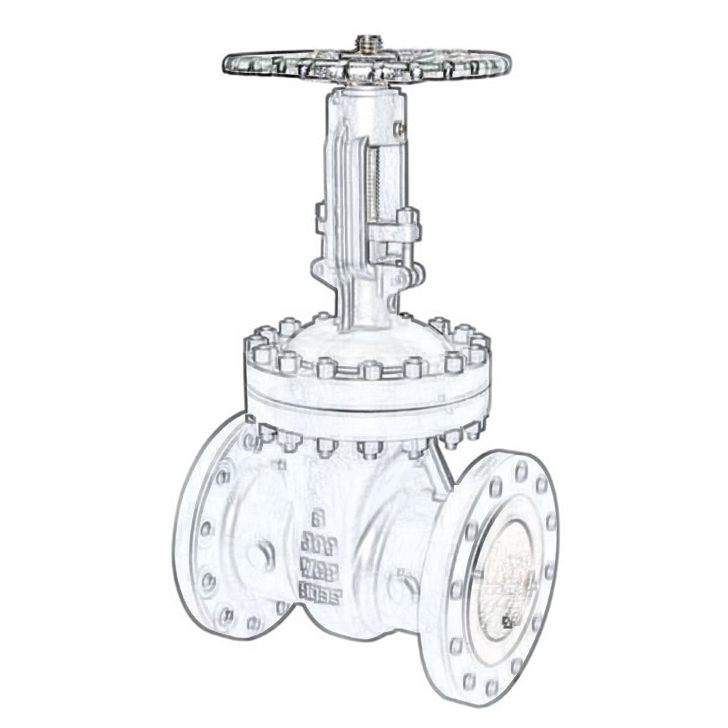

Bolted Bonnet Forged Check Valve

Bolted bonnet check valve automatically open and close discs depending on the flow of the medium to prevent medium backflow. It can be can be divided into swing check valves and lift check valves.

- category :Forged Check Valve

- Email :teji@teji-valve.com

- Phone :+86-577-67354000

- fax :+86-577-67354001

PRODUCT INTRODUCTIN

Bolted bonnet forged check valve belongs to the automatic valve class, also known as one-way valve backflow valve or isolation valve, can automatically open and close discs depending on the flow of the medium to prevent medium backflow. It can be divided into swing check valves and lift check valves. The combination of check and globe valves provides safety isolation.

FEATURES

1. Compact and reasonable structure, reliable sealing and excellent performance;

2. Small size and light weight;

3. Wide application range;

4. The valve disc closes quickly and moves sensitively;

5. The closing impact is small and water hammer is not easy to occur;

6. The flow channel is unobstructed and the fluid resistance is small.

APPLICATION CRITERIA

Design: API602/ASME 16.34/BS 5352

Pressure Test: API 598/ EN12266

Flange Ends: ASME B16.5/ EN1092

SW Socket Welding Ends:ASME B16.11

BW Buttwelding Ends: ASME B16.25

NPT Threaded Ends: ASME B1.20.1

Note: End dimension can be manufactured according to customer's requirements.

PRESSURE RATING

CLASS 800

CLASS 1500

CLASS 2500

SPECIFICATION

Size range: 1 / 2 "~ 2" (DN15~DN50)

Pressure Rating: 150LB~2500LB

OPTIONAL MATERIALS

Carbon Steel: ASTM A105, ASTM A350 ASTM LF2

Stainless Steel: ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L

Duplex Steel: ASTM A182 F51, ASTM A182 F55,ASTM A182 F53

Alloy Steel: ASTM A182 F1, ASTM A182 F5, ASTM A182 F5A, ASTM A182 F9, ASTM A182 F11, ASTM A182 F22

NOTICE

Do not allow the check valve to bear weight in the piping system. Large check valves should be independently supported to protect them from the pressure generated by the piping system.

Pay attention to the direction of medium flow during installation in the same direction as the arrow marked on the valve body.

Welcome to our website. If you have any requests or suggestions,please feel free to email us at teji@teji-valve.com or use the following enquiry form. Please allow us to provide you with the best service.