Product Detail

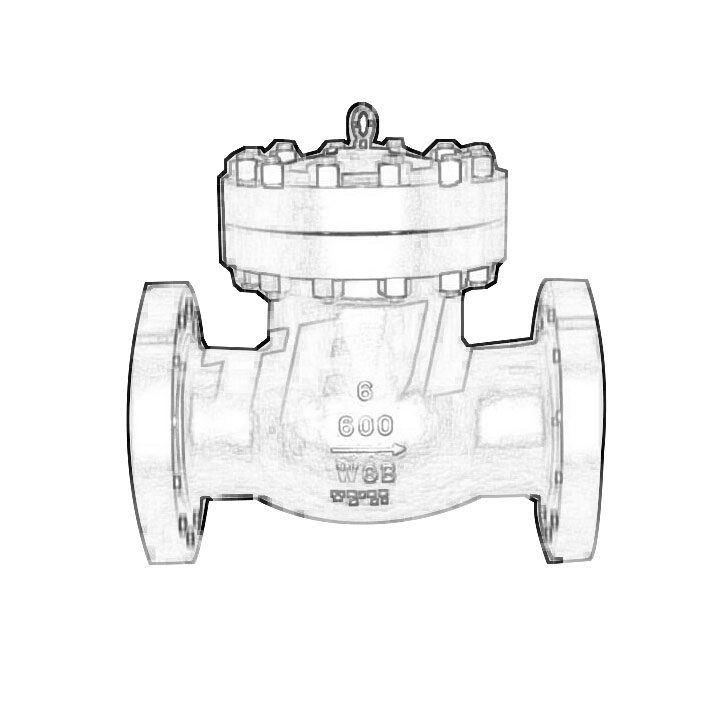

Knife Gate Valve

Knife Gate Valve Overview Its opening / closing part is a shutter, and the movement direction of the shutter is perpendicular to the fluid direction. Knife gate valves completely solved the problems of GATE ,BALL, GLOBE REGULATING, BUTTERFLY and other valves with large flow resistance and heavy...

- category :Gate Valve

- Email :teji@teji-valve.com

- Phone :+86-577-67354000

- fax :+86-577-67354001

Knife Gate Valve

Overview

Its opening / closing part is a shutter, and the movement direction of the shutter is perpendicular to the fluid direction.

Knife gate valves completely solved the problems of GATE ,BALL, GLOBE REGULATING, BUTTERFLY and other valves with large flow resistance and heavy weight due to their small size, small flow resistance, light weight, easy installation and easy disassembling. Problems such as difficult installation and large footprint. Up till now, the largest amount of knife gate valves in the world is the United States and Japan.

Features

The knife gate valve has a good shearing effect due to the use of the knife gate. Widely used in paper making, petrochemical, mining, drainage, food and other industries.

Our available material: cast iron, carbon steel, stainless steel, size range: DN50 ~ DN600,

maximum pressure: 1.0MPa.

Design Standard: ASME, JIS.

Sealing Method

SEALING FAC

SEALING FAC

UNSEALED FACE

UNSEALED FACE

SEALING FACE UNSEALED FACE

When the knife gate valve is closed, the sealing surface can only rely on the medium pressure to seal, the medium pressure is used to press the sealing surface of the gate to the valve seat on the other side to ensure the sealing surface. Most knife gate valves are forced to seal, that is, when the valve is closed, it must rely on external force to force the gate to the seat to ensure the sealing surface sealing. This type of valve should generally be installed horizontally in the pipeline. An O-shaped seat can be used to achieve bidirectional sealing if a higher medium tightness is required.

TIP: The difference between the sealed surface and the unsealed surface can be distinguished from the picture above.

Structure

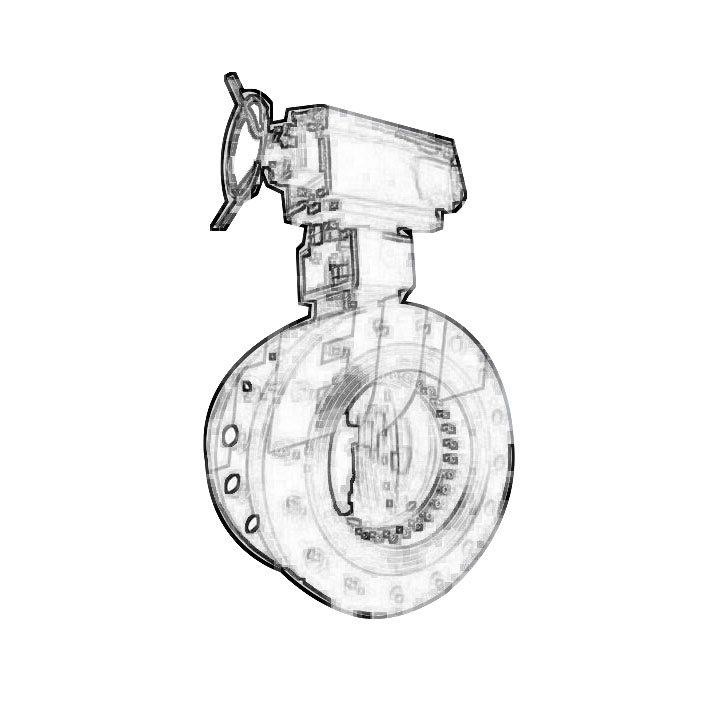

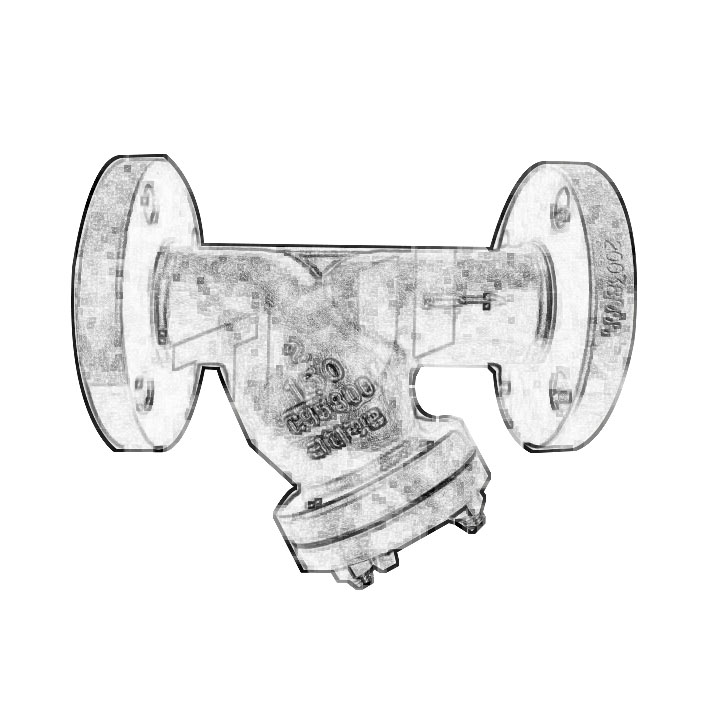

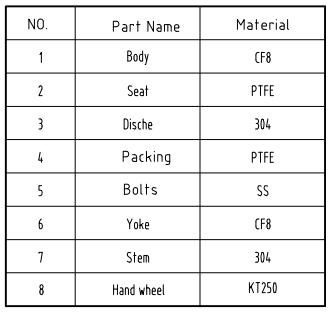

Drawing (SS Wafer Type Knife Gate Valve)

Advantages

1. The valve adopts integral design, with low fluid resistance and flexible and convenient operation.

2. Light weight: The body is made of carbon steel, and the weight is reduced by about 20% -30% compared with the weight of the traditional gate valve, which is convenient for installation and maintenance.

3. The screw drive of the manual knife gate valve adopts a double plane bearing design, which greatly reduces the friction of the transmission, so that the valve can be opened smoothly and smoothly.

4. The sealing seat of the knife gate valve adopts a movable seal, and the O-ring preload is used to provide the preloading force, so that the sealing seat is close to the valve flap, the leakage is greatly reduced, and the automatic compensation function for the wear of the sealing pair in long-term use is improved. The service life.

5. Fixed guide claw, no groove design, not easy to cause medium accumulation or jamming.

6. Valve seat can choose metal hard seal or soft seal according to the needs of medium and working conditions: the gate is chrome plated or ion nitrided to make the gate more wear-resistant and the sealing surface has a longer service life; soft seal is optional PTFE seat or reinforced PTFE seat or EPDM, NBR, good sealing and corrosion resistance.

7. Wide range of medium adaptability: good sealing performance and strong economic practicability, the operation can be manual, pneumatic, electric, and the practical range is very wide.

Welcome to our website. If you have any requests or suggestions,please feel free to email us at teji@teji-valve.com or use the following enquiry form. Please allow us to provide you with the best service.